Splicing Fiber Optic Cables for Reliable Networks

Today, fast internet is part of daily life. People use it for work, school, gaming, video calls, and smart home devices. Behind all of this speed is something called fiber optic cable. Fiber carries data using light, not electricity, which makes it much faster and more reliable than older wiring.

But fiber cables are not always perfect forever. Sometimes they break, get damaged underground, or need to be extended. That is where splicing comes in. Strong fiber connections help keep networks running smoothly with less downtime and fewer signal problems.

In this blog, you will learn what fiber splicing means, how it works, what tools are used, and when it is best to call an expert.

What Does Splicing Fiber Optic Cables Actually Mean?

Splicing Fiber Optic Cables means joining two fiber optic cable ends together so light signals can travel through without interruption. This is one of the most important steps in building or repairing fiber networks.

When a cable gets cut, or when installers need to connect long cable runs, they splice the fiber strands inside. Each strand is very thin, even thinner than a hair. That is why fiber optic splicing requires careful work, proper tools, and a clean environment.

Splicing helps create strong, long lasting connections. It also reduces signal loss, which keeps internet and communication systems working at top performance.

What Is Optical Fiber Splicing and How Does It Work?

Optical fiber splicing is the process of connecting two optical fibers together. The goal is to make the connection so smooth that light can pass through almost like the fiber was never cut.

Fiber optic splicing works by aligning the fiber cores, the center part that carries light. If the alignment is off, even by a tiny amount, the signal can weaken.

Professionals use special fiber optic splicing equipment to:

Strip the protective coating

Clean the fiber ends

Cut the fiber evenly

Join the fibers using heat or connectors

Protect the splice area

This process helps prevent future failures and keeps networks stable.

Types of Splicing Methods and Their Importance

There are two main types of splicing fiber optic cable methods. Each one has its own use depending on the job.

Fusion Splicing

Fusion splicing fiber optic cable uses a fusion splicer machine to join two fiber ends together with heat. The fibers are carefully aligned, then melted into one smooth connection. This method creates a very strong splice with very low signal loss. It is the most common choice for permanent fiber optic cable installations, long distance networks, and underground fiber repairs.

Mechanical Splicing

Mechanical splicing connects fiber ends using a special alignment sleeve or connector instead of heat. It is usually faster and easier for quick repairs or smaller projects. However, it can have slightly more signal loss compared to fusion splicing and may not be as durable for long term outdoor use.

Both methods are important in fiber optics splicing. The best option depends on the network needs, budget, and whether the splice is meant to be temporary or permanent.

Fusion Splicing Fiber Optic Cable Explained Step by Step

Fusion splicing is the gold standard in fiber optic fusion splicing. It gives the cleanest connection and the best performance.

Here is how professionals do it:

Prepare the cable

The outer jacket is removed carefully.Strip the fiber coating

The fiber inside is exposed using fiber optic cable splicing tools.Clean the fiber

Alcohol wipes remove dust and oils.Cleave the fiber ends

A cleaver makes a smooth, flat cut.Use a fusion splicer machine

The optical fusion splice machine aligns the fibers perfectly.Fuse with heat

The splicer melts the ends into one continuous fiber.Protect the splice

A sleeve is added for strength.

Fusion splice fiber optic cable connections are strong, long lasting, and trusted in high performance networks.

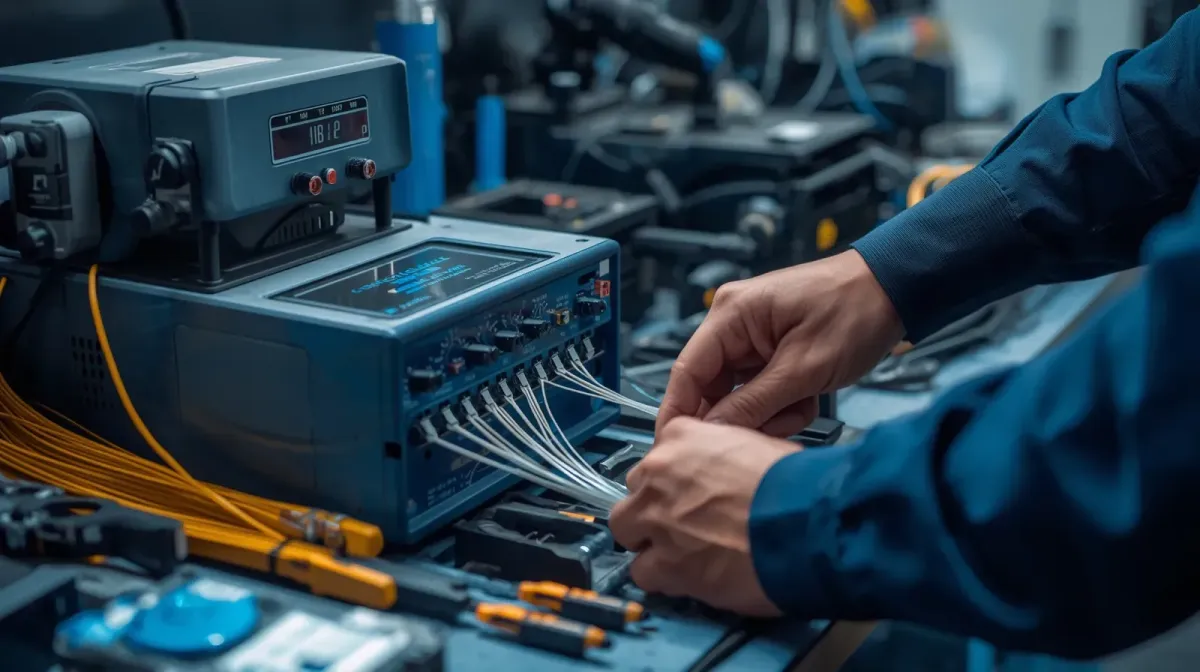

Fiber Optic Splicing Tools and Equipment Professionals Use

Fiber splicing is not a job you can do with basic hand tools. It requires special fiber optic splicing tools and equipment designed for precision.

Common tools include:

Fiber splicing kit

Fiber optic splicer tool

Fiber optic splicer machine

Fiber cleaver

Fiber optic cable repair tools

Cleaning supplies

Splice protectors

Fiber splice on connectors

A complete fiber splicing tool kit helps technicians work faster and safer. Brands like Corning fiber tools are also popular for quality and reliability.

Using the right splicing fiber optic cable equipment prevents errors and improves network performance.

What Is a Fiber Optic Splicer Machine and Why It Matters

A fiber optic splicer machine is the device used for fusion splicing. It is also called an optic fiber splicer or optical fiber fusion splicer tool.

This machine is important because it:

Aligns fiber cores automatically

Creates low loss splices

Reduces human error

Works quickly and accurately

Without this technology, fiber fusion splicing would be much harder and less reliable.

Professional splicer fiber optic systems also include testing tools to confirm signal strength after the splice is complete.

Can You Splice Fiber Optic Cable Without a Machine?

Many people ask, can you splice fiber optic cable at home? Or can fiber optic cable be spliced without a machine?

The simple answer is: sometimes, but it is risky.

Mechanical splicing can be done without a fusion splicer, but it still needs special splicing kit for fibre optic cable parts and steady hands. DIY splicing fiber optic cable without machine often leads to:

Weak signal

Higher loss

Poor alignment

Shorter connection life

Fiber optic wire is delicate. Even small dust particles can ruin the splice. That is why most experts recommend professional optical fiber splicing for important networks.

Common Fiber Cable Splicing Mistakes That Cause Signal Loss

Fiber cable splicing must be done carefully. Mistakes can cause problems that are hard to fix later.

Common errors include:

Dirty fiber ends

Poor cleaving angles

Misaligned fiber cores

Using the wrong fiber optic tool

Skipping splice protection

Rushing the process

Splicing underground cable is even more challenging because moisture and dirt can enter the connection area.

Good fiber optic splicing equipment and trained technicians help avoid these issues and keep networks running smoothly.

Fiber Optic Cable Splicing Services in Surprise, AZ by DataTel

When fiber networks need repairs or upgrades, working with trained professionals makes a big difference. DataTel provides expert fiber optic cable splicing services with the right tools, experience, and safety practices.

Whether it is fiber optic ribbon splicing, fiber splice repairs, or full network expansion, skilled technicians use proven splicing technology to deliver clean, reliable results.

A professional team understands how to splice fiber optic wire correctly, test the connection, and protect the cable for long term use. DataTel brings trusted solutions for businesses and systems that depend on strong fiber performance.

When to Call Experts for Fiber Optic Cable Splicing and Repair

Fiber optic splicing is not just about connecting cables, it is about protecting the steady flow of data that keeps modern life running. You should call an expert if your fiber cable is damaged or cut, if you need a permanent fusion splice connection, or if you want low loss, high speed performance. Professional help is also important when installing new fiber optic cable runs or when your network depends on reliable communication every day. With the right fiber splicing equipment, proper training, and careful testing, the job gets done correctly the first time. If you want strong, clean, and lasting fiber connections, reach out to DataTel today. A quick consultation can help you choose the best splicing solution and keep your network running smoothly without stress.